mixing nozzels

UGELLI MAZZEI

Mixing Nozzels

The nozzles are located downstream with respect to the injector to boost its effect; feeding the liquid with the gas finely dispersed in a contact tank, they make it possible to draw more liquid, facilitating mixing and increasing the efficiency of the gas/liquid transfer.

Advantages deriving from the use of nozzles:

- Increases the efficiency of the aeration system based on Mazzei injectors

- Enables the transfer of gases at all depths

- Large quantities of gas can be used (e.g. ozone)

- Compact design for easy installation

- Robust construction in PVDF

- Various models proposed to meet all system requirements

Various models are available in sizes from 1" to 6". The curves displayed show the performance of the various models in terms of the relationship between flow rate and pressure drops.

Complete aeration system:

The gas transfer system based on injectors and nozzles can be engineered with many variants so as to adapt to the requirements of each specific application.

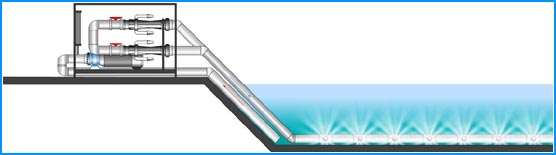

The patented Mazzei AirJection System, for example, uses a group of injectors outside the tank and a piping with nozzles placed under the surface of the liquid, normally resting on the bottom. The pump can be submerged or external.

Another installation technique is to transfer the gas by means of floating piping (Floating Air Jection System). The system uses an injector to transfer the gas into the liquid. The aerated mixture is conveyed by means of floating collectors and then towards the bottom of the tank with descending tubes; it then enters the nozzles which transfer the mixture into the surrounding water. The micro-bubbles formed pass through all of the liquid and emerge on the surface.

This technique is particularly interesting for application in existing tanks, in that it allows for intervention without the need of emptying the tank.

In any case, porous diffusers or blowers are not used. The system requires no maintenance as there are no moving parts, other than a liquid recirculation pump.

SEPRA provides complete assistance for sizing, installation and testing of the aeration systems.

Oxygen injection system:

The injector and nozzle based system is also found to be particularly efficient in cases where pure oxygen has to be transferred into a tank or tubing.

The water in which the oxygen is to be introduced is moved with an appropriate pump; the injector is installed on the delivery side of the pump, making it possible to bring the dissolved gas to a pressure higher than that of the atmosphere or of the simple liquid head. The resulting oversaturated gas/liquid mixture is fed into the tank by means of nozzles which mix it with oxygen-poor water, facilitating its immediate use and increasing the efficiency of the system.

At the same time the jets created by the nozzles ensure the complete mixing of the tank in which oxygen is injected.

The systems designed by SEPRA allow the use of oxygen even if it is available at low pressure and are therefore a particularly attractive choice in cases where there is a need to use gas coming from other processes (e.g. exhausted oxygen from ozonation processes). The injectors in fact guarantee a considerable gas-extraction capacity, also in the case of very deep tanks.

Ask for information